Products

Optimized & Industry-ready Solutions

For All Your Complicated Needs

“We offer comprehensive solutions for all your complex plastic injection moulding needs, providing tailored approaches that address even the most intricate challenges. With years of expertise and advanced technology, we specialize in delivering highly precise and durable parts that meet the most demanding specifications. From custom mould designs and multi-material applications to high-precision moulding for intricate geometries, we tackle every challenge with innovation, ensuring exceptional performance, cost-efficiency, and on-time delivery. No matter how complex your requirements, we have the expertise and resources to turn your vision into reality.”

Our Innovations

Industry Focused Products!

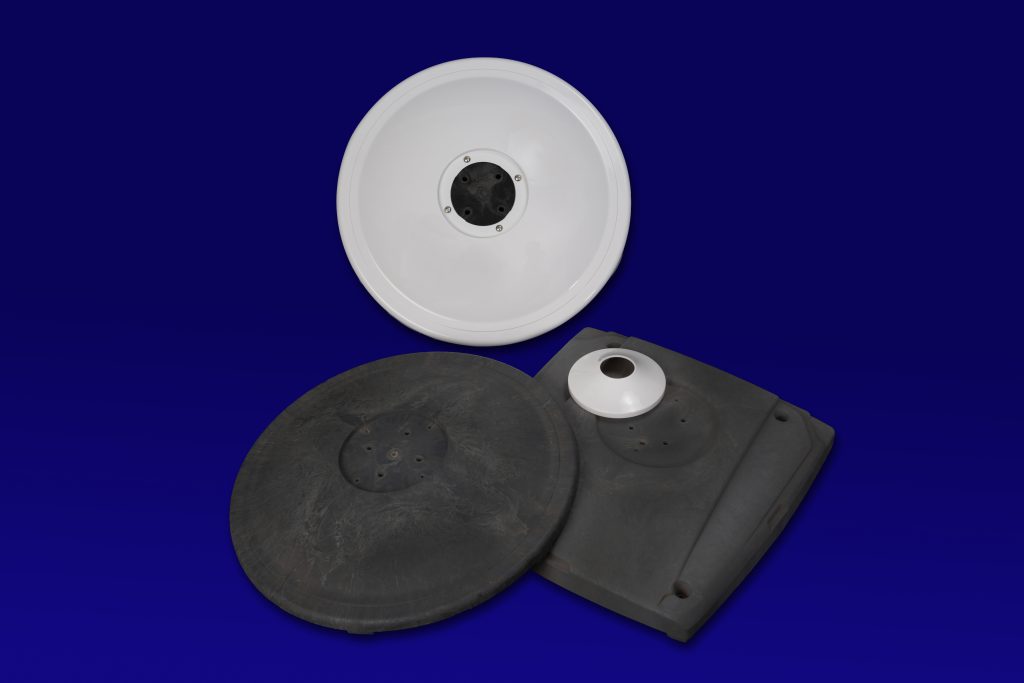

Ceiling Fan Components

The canopy is a sleek cover that conceals the wiring and electrical connections between the ceiling and the fan. Crafted from durable metal or plastic, it is designed to seamlessly complement the fan’s style, adding both functionality and aesthetic appeal.

Electrical Junction Box

An electrical junction box is an enclosure used to house and protect electrical connections. It serves as a central point where wires from different circuits are joined together. Junction boxes help organize wiring, prevent accidental contact with live wires, and provide protection from dust, moisture, and tampering. They are typically made of plastic or metal and are essential for both safety and code compliance in electrical installations.

Moulded Articles

Moulded articles are objects manufactured by shaping materials—such as plastics, rubber, or metals—using moulds. These articles are produced with precise shapes and dimensions for specific applications, offering advantages like high strength, uniformity, and efficient mass production. Moulded products are widely used in industries such as automotive, electrical, consumer goods, and packaging due to their durability, design flexibility, and cost-effectiveness.

Industrial Spacers

Industrial spacers are components used in a variety of industrial applications to maintain a precise gap or distance between two parts or surfaces. These spacers are designed to ensure proper alignment, prevent contact between parts, and enable smooth operation in machinery and equipment. They are widely used in industries such as manufacturing, automotive, electronics, construction, and aerospace

Pedestal Fan Base

A pedestal fan base is the bottom supporting structure that provides stability to the entire fan unit. It is typically made from durable materials like plastic or metal and is designed to evenly distribute the fan’s weight, preventing tipping during operation. The base often features a wide, flat surface or a cross-shaped design for balance, and may include added weight or anti-slip pads for enhanced safety and stability.

Electrical Terminals

Electrical terminals are connection points used to join electrical conductors to devices, components, or other conductors. They ensure a secure and stable electrical connection and are commonly made from conductive materials such as copper, brass, or aluminum. Terminals come in various forms, including screw terminals, spade terminals, ring terminals, and push-on connectors, and are used in applications ranging from household wiring to industrial machinery. They are essential for enabling safe, efficient, and reliable electrical connectivity.

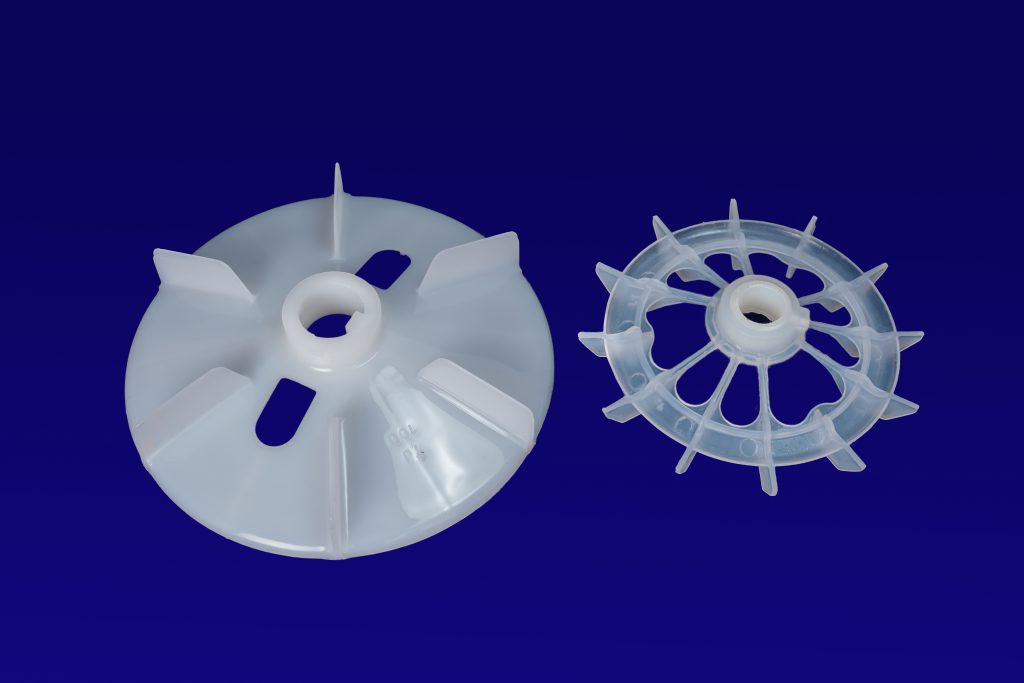

Motor Fan

A motor fan is a mechanical device attached to or integrated with a motor to provide cooling by dissipating heat generated during operation. It typically consists of rotating blades that move air across the motor’s surface, helping maintain optimal operating temperatures and prevent overheating. Motor fans are commonly found in electric motors, automotive systems, industrial machinery, and household appliances, ensuring efficient performance and extending the motor’s lifespan.

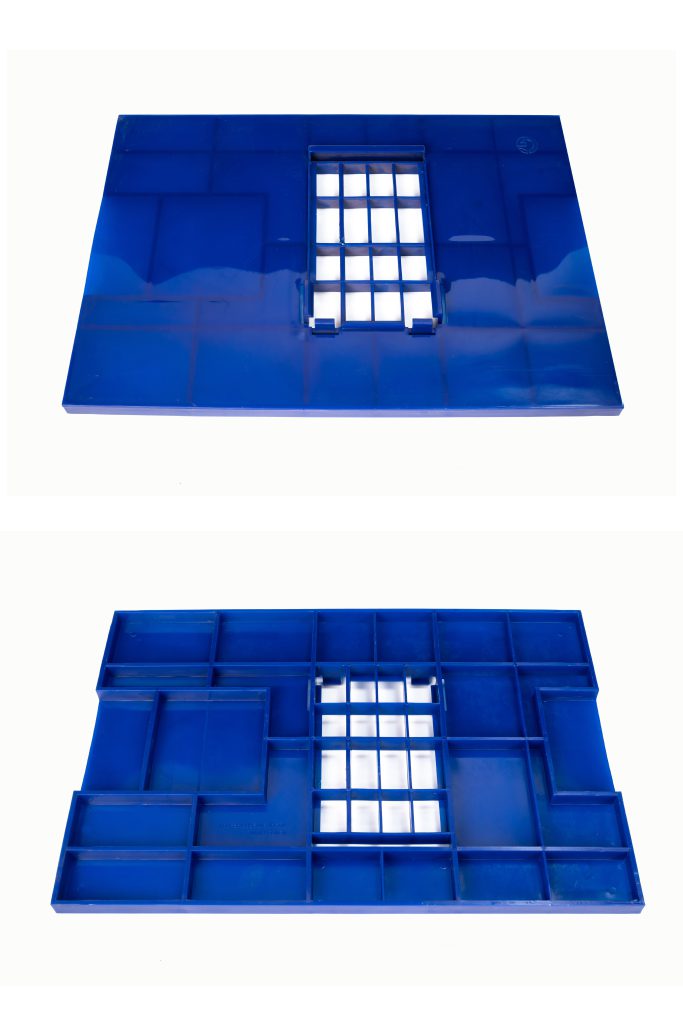

Motor Base

A motor base is a lightweight yet durable platform designed to support and secure electric motors. Manufactured from high-strength engineering plastics, it offers excellent resistance to corrosion, moisture, and chemicals, making it suitable for various indoor and outdoor applications. The base provides stability and alignment for the motor, often featuring integrated mounting slots or holes for easy installation. Its non-conductive and vibration-dampening properties enhance motor performance while reducing noise and wear, making it a cost-effective and reliable choice in appliances, HVAC systems, and light-duty machinery.

Insert Moulding

Insert moulding is a manufacturing process where metal or other components are placed into a mould and encapsulated with plastic to form a single integrated part. This technique combines the strength of inserts (such as threaded bushings, terminals, or pins) with the flexibility and insulation properties of plastic. It enhances part performance, reduces assembly time, and increases durability. Insert moulding is widely used in electrical, automotive, medical, and consumer electronics industries for producing strong, reliable, and lightweight components.

Soft Bushes

A soft bush component features a flexible or elastomeric bushing that is used to cushion and isolate mechanical parts. These bushings absorb shocks, vibrations, and noise, helping to reduce wear and improve performance in dynamic applications. Commonly made from rubber or other soft polymers, soft bushes are used in automotive suspensions, machinery mounts, and rotating equipment to enhance comfort, reduce stress on components, and extend service life.